Force Calibration Services in Southern California

Force Calibration Services from QSI

Accurate force measurement is fundamental to ensuring product quality, safety, and performance across countless industries, from materials testing and manufacturing to aerospace engineering and construction. When force measuring instruments drift out of calibration, the consequences can be severe—compromising structural integrity assessments, invalidating quality control data, creating safety hazards, and resulting in costly product failures.

Quality Surveillance, Inc., backed by the trusted Accredited Labs network, provides comprehensive force calibration services that ensure your force measurement systems deliver the precision and reliability your critical applications demand.

What is Force Calibration?

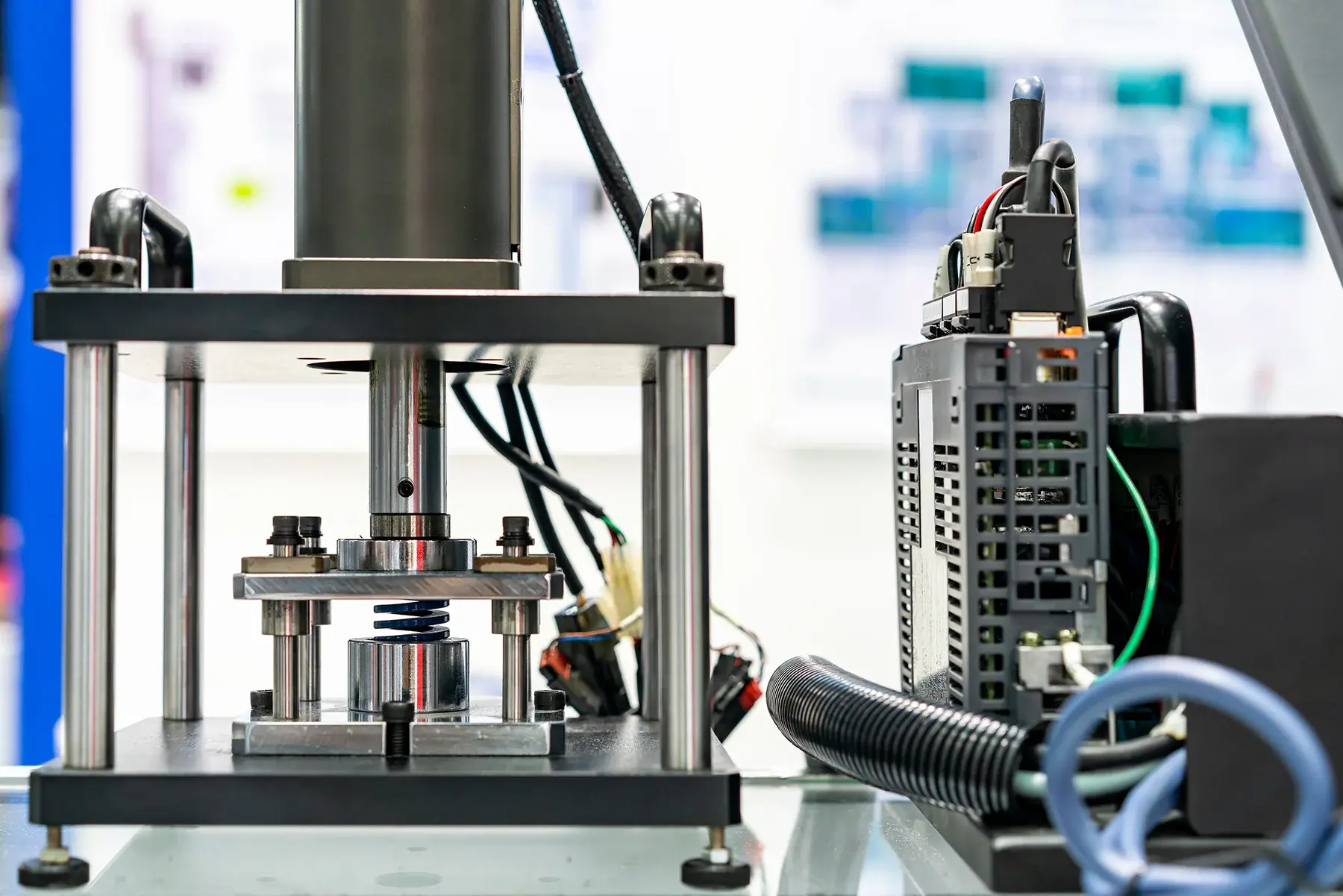

Force calibration is the systematic process of verifying and adjusting force measuring instruments to ensure they accurately measure push, pull, compression, and tension forces across their specified measurement ranges. This essential service compares your force instruments against certified reference force standards with known, traceable values to identify any deviations from their specified accuracy ranges.

During force calibration, skilled technicians evaluate each instrument's performance using precisely applied forces throughout the instrument's measurement range. They document any measurement variations discovered and perform necessary adjustments to restore accuracy to manufacturer specifications. When instruments cannot be adjusted to meet their original specifications, detailed calibration reports provide the deviation data essential for your corrective actions and informed maintenance or replacement decisions.

The calibration process follows rigorous protocols established by international standards, ensuring consistency, reliability, and traceability. Each calibrated force instrument receives comprehensive documentation that traces its accuracy back to national force measurement standards, providing the measurement traceability that quality management systems, safety regulations, and testing standards require.

Why Force Calibration is Critical for Your Operations

Product Safety and Structural Integrity

Force measurements are often directly related to safety-critical applications where inaccurate readings can have catastrophic consequences. Whether testing material strength, verifying fastener torque, or assessing structural load capacity, accurate force measurement is essential for ensuring products and structures can safely withstand their intended loads throughout their service life.

Quality Control and Material Testing

Manufacturing and construction industries depend on precise force measurements to verify material properties, validate product performance, and ensure compliance with specifications. From tensile testing of materials to compression testing of components, calibrated force instruments provide the accurate data necessary for quality decisions and regulatory compliance.

Research and Development Accuracy

Engineering research, product development, and materials science rely on accurate force measurements to understand material behavior, validate design calculations, and develop new products. Inaccurate force measurements can invalidate research results, lead to incorrect design assumptions, and compromise product development programs.

Manufacturing Process Control

Production processes often incorporate force measurements for quality control, assembly verification, and process monitoring. Whether controlling press forces, monitoring assembly loads, or verifying joint integrity, accurate force measurement ensures consistent product quality and helps prevent manufacturing defects.

Regulatory and Standards Compliance

Industries from aerospace to medical devices operate under strict testing standards that require traceable force measurements. Standards like ASTM, ISO, ANSI, and industry-specific requirements mandate that force measuring equipment be properly calibrated and maintained to ensure valid test results and regulatory compliance.

Cost Avoidance and Risk Management

Inaccurate force measurements can lead to over-designed products that waste materials and increase costs, or under-designed products that fail in service and create liability issues. Proper force calibration helps optimize designs, reduce material waste, and minimize the risk of product failures and associated costs.

Why Choose QSI for Force Calibration?

At Quality Surveillance, Inc. we combine the personalized service of a local provider with the resources and reliability of a national network.

Powered by Accredited Labs

As part of the Accredited Labs family, Quality Surveillance, Inc. combines local, personalized service with the resources and expertise of a national calibration network. This partnership ensures consistent quality, technical support, and the capabilities needed to handle your most challenging calibration requirements.

Personalized Customer Service

We believe in building long-term relationships with our customers. That's why we prioritize clear communication, consistency, and reliability. Our team takes time to understand your specific needs, applications, and challenges, so we can provide calibration solutions that support your operational goals and quality objectives.

ISO/IEC 17025 Accreditation

We operate under the rigorous ISO/IEC 17025 standard, which demonstrates our technical competence and quality management system. This internationally recognized accreditation means our calibration results are accurate, reliable, and globally accepted. Our technicians undergo continuous training in evolving technologies and techniques.

Comprehensive Documentation

We go beyond calibration certificates, providing you with the documentation and support your quality system needs. Our detailed reports include measurement data, uncertainty analysis, and recommendations for calibration intervals. We also maintain comprehensive records for easy certificate retrieval and audit support.

Flexible Service Options

We understand that every business has unique operational requirements. That's why when possible we offer on-site calibration services to reduce your downtime. For instruments requiring controlled environments or specialized equipment, our fully equipped laboratories provide optimal calibration conditions.

Fast Turnaround Times

Production schedules don't wait for calibration delays. We prioritize quick turnaround times without compromising quality, helping you maintain operational efficiency while meeting calibration requirements. Our streamlined processes and scheduling ensure your instruments return to service as quickly as possible.

Audit-Ready Force Calibration in 3 Simple Steps

Submit Your Equipment List

Send us a list of the equipment you need calibrated, and we’ll provide a tailored quote with clear pricing—no hidden fees.

Schedule Your Calibration

Choose a convenient time for an in-lab or on-site equipment calibration. Our certified technicians ensure precision and compliance with ISO/IEC 17025 standards.

Stay Compliant & Audit-Ready

Receive detailed calibration reports and certification, giving you peace of mind for audits and operational excellence.